What Is Tertiary Wastewater Treatment, and How Does It Work?

By: Tom Frankel

Post Date: December 2nd 2020

In the wastewater industry, plants often focus on primary and secondary treatments, which do most of the work of preparing wastewater for discharge into the environment. Tertiary treatment is also critical in many situations. It affords the peace of mind of knowing that the treated wastewater is clean, sanitary, compliant with regulations and safe enough for drinking or reuse.

The guide below will discuss how tertiary wastewater treatment works and elaborate on some different types of tertiary filtration and disinfection methods.

Table Of Contents

- What Is Tertiary Wastewater Treatment?

- How Does Tertiary Wastewater Treatment Work?

- Contact SSI Aeration, Inc. for All Your Tertiary Treatment Needs

What Is Tertiary Wastewater Treatment?

What is tertiary treatment in wastewater? To answer this question, let’s look into how treatment plants generally work and how the main stages of wastewater treatment progress.

Most wastewater treatment systems consist of at least two main treatment processes: primary and secondary treatment, with some additional preliminary methods. Primary treatment, which typically removes 50% to 70% of the suspended solids in wastewater, uses physical processes like filtration and settling to remove grit, debris, oil, grease and some lighter solids. Secondary treatment applies additional biological processes like aeration and activated sludge treatment to break down dissolved and suspended biosolids using good bacteria.

Tertiary treatment adds a third, more advanced and rigorous level of treatment. Primary and secondary treatment typically get wastewater only clean enough to discharge safely into the environment. Tertiary treatment, on the other hand, can achieve levels of water purification that make the water safe for reuse in water-intensive processes or even as drinking water.

Not all wastewater treatment plants use tertiary treatment. Primary and secondary treatment are often sufficient for many purposes. Those that do use tertiary treatment achieve more stringent levels of cleanliness to meet the exacting standards that govern water reuse, especially in public water supplies. Tertiary treatment is also beneficial when facilities must discharge water into sensitive aquatic ecosystems such as estuaries, sluggish rivers or waters close to coral reefs.

It is more effective than primary or secondary treatment at removing unwanted color from wastewater, so it is essential in industrial pulp and paper applications and textiles manufacturing.

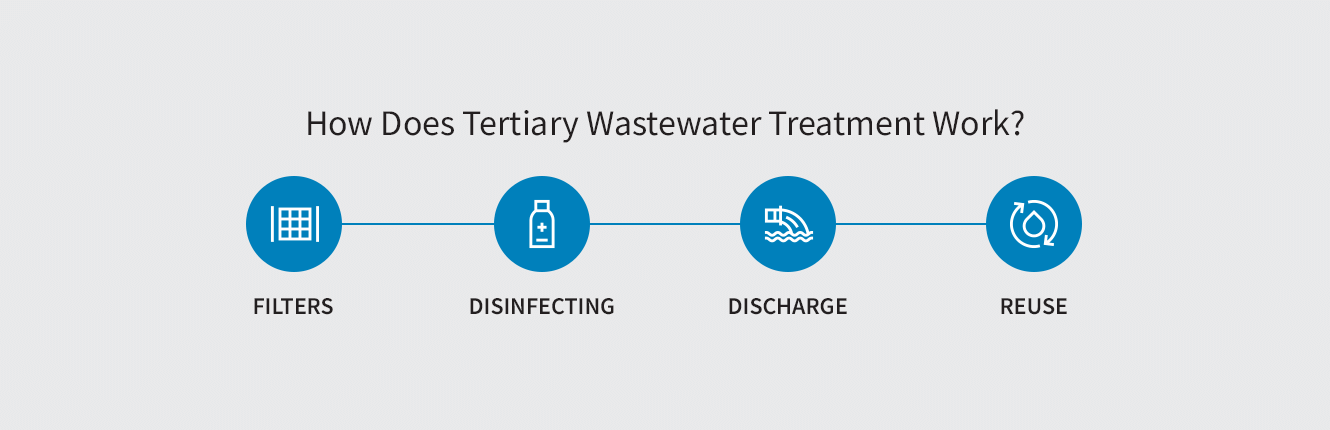

How Does Tertiary Wastewater Treatment Work?

Tertiary wastewater treatment often works by using a combination of physical and chemical processes to remove harmful microbiological contaminants from wastewater. The process usually involves filtration followed by additional disinfecting treatment. In some cases, tertiary treatment may also use other specialized treatments like lagoon storage, biological nutrient removal, and nitrogen and phosphorus removal.

Filters

Tertiary filtration components can contain a few different materials. Sand and activated carbon filters are common, and filters can also contain fine woven cloth. The filters also come in a few different types, including bag filters, drum filters and disc filters:

- Bag filters: Bag filters are ideal for wastewater treatment plants that need to reduce contaminants to a specific micron rating. They can be made of felt to serve as depth media or made from mesh to serve as surface media. Bag filters and housings come in various shapes and sizes, including single and multi-bag filters and plastic and metal housings, so they are useful across a range of treatment plants and equipment.

- Drum filters: A drum filter consists of a drum with a woven cloth filter around it. Gravity sends wastewater flowing into the filter via the central drum. Media mounted on the drum then separate the solid particles from the water, and the filtered water moves through the media and into the collection tank. Once the separation is complete, backwash cleans the media components to ensure their continual functioning.

- Disc filters: A disc filter consists of a central drum attached to multiple discs with cloth filters. Gravity pushes wastewater from the drum into the filters in an inside-out flow pattern. Then media mounted on each side of the discs separate solid particles from the liquid. Clean water flows into a collection tank, and backwash cleans the media once they become saturated with particles.

Disinfecting

The process of tertiary disinfection may take a few different forms:

- Chlorine treatment: Chlorine is one of the most commonly used disinfectants in wastewater treatment, particularly in North America, because it is budget-friendly, easy to use and effective. Wastewater treatment plants can dump chlorine into the wastewater to kill harmful microorganisms like bacteria and viruses. However, chlorine can harm aquatic ecosystems, so chlorinated wastewater requires dechlorination before discharge into the environment. When chlorine reacts with organic material, it can also sometimes form potentially carcinogenic compounds like trihalomethanes and mutagen X.

- Ultraviolet light treatment: Ultraviolet (UV) light is a common disinfectant in tertiary treatment. The wastewater flows under banks of UV lights, and the light sterilizes microorganisms by damaging their genetic structures. Ultraviolet light does not typically kill viruses and bacteria, but it renders them unable to infect humans or wildlife. The effluent must have received aggressive treatment beforehand, though, because any residual organic matter can shield the microorganisms from the UV light. The lamps also require a relatively high level of maintenance.

- Ozone treatment: An alternative method is to use ozone — a compound formed by using electrical energy to add a third oxygen atom to standard diatomic O2 — as a disinfectant. Ozone is highly reactive and can destroy most microorganisms it comes into contact with. It is safer than chlorine because plants can generate it on-site as needed rather than storing it over the long term and risking a toxic leak. It also will not form hazardous byproducts in the water. The treatment equipment is relatively expensive to maintain, however.

Discharge

Once the wastewater has undergone tertiary treatment, it is ready for discharge back into the environment. Many municipalities have specific requirements about the discharge of treated water, and tertiary treatment should be sufficient to meet those standards, keep the environment clean, and preserve human health.

Reuse

Many treatment plants use tertiary treatment specifically to make the water safe for human ingestion. After tertiary treatment, the water has undergone sufficient purification to be as clean and healthy as drinking water. Water that has received tertiary treatment is also suitable for numerous operations that require clean water, such as industrial and manufacturing processes, oil and gas extraction and refining, utility cooling, and agricultural practices like irrigation.

Contact SSI Aeration, Inc. for All Your Tertiary Treatment Needs

To receive assistance with your tertiary wastewater treatment system, make SSI Aeration your trusted source. As a full-service wastewater treatment engineering company, SSI has the experience and industry expertise to help you improve your treatment’s efficiency or meet environmental regulatory standards for your discharged wastewater. We offer comprehensive system design and engineering and are happy to assist with lab services, field services, and treatment product selection.

Start your quote today, or contact us to learn more.

Mr. Frankel co-founded SSI in 1995 with experience in design and distribution of engineered systems. He is in charge of sales, marketing and operations in the company. Mr. Frankel holds multiple US patents related to diffusers. He is a graduate of Washington University in St. Louis.