Corporate Social Responsibility

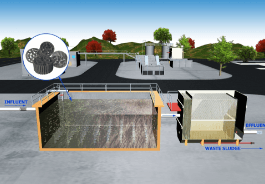

SSI Aeration takes its mission of providing aeration systems for industrial and municipal wastewater treatment plants with great seriousness. As the years have gone by, we realized there was a way we could achieve our mission and do more for the community. At our Poughkeepsie Headquarters, we have taken this idea in a surprising direction.

Todd Ritter, of the SSI Executive Team, explains: “we discovered that the precision fabrication, manufacturing and shipping we require could be provided locally. SSI supports local business and charities in each of the markets we serve and are proud to be involved in the communities where our systems are installed”

Learn More